AeroBarrier

AeroBarrier is an advanced, automated duct sealing technology that targets and seals invisible leaks from the inside out.

EnviroAir Solutions, LLC »Aerobarrier

AeroBarrier is an award-winning technology used in full-gut remodels and new construction to effectively seal air leaks in residential and commercial buildings. It utilizes a powerful fan to pressurize the structure and distribute a fog-like sealant. As air escapes through gaps and cracks, it carries the sealant directly to the leak sources, where it quickly seals them—delivering a tighter building envelope, improved energy efficiency, and a consistently high-performance, leak-free property.

Sealing the envelope brings cost savings, prevents air and moisture transfer, prevents mold growth, and creates a more comfortable space. AeroBarrier helps builders consistently meet or exceed codes and regulations. There’s no need to manually caulk every crack or seam.

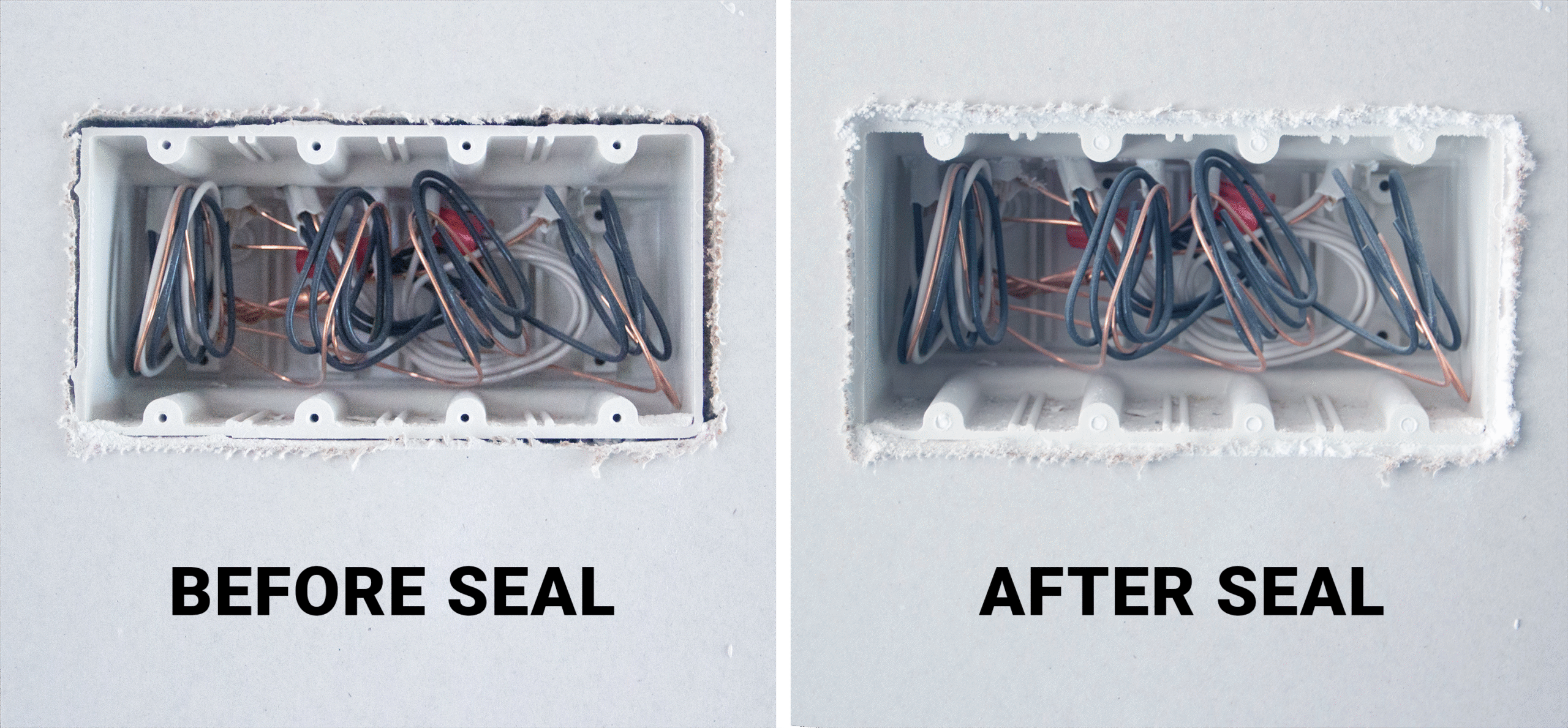

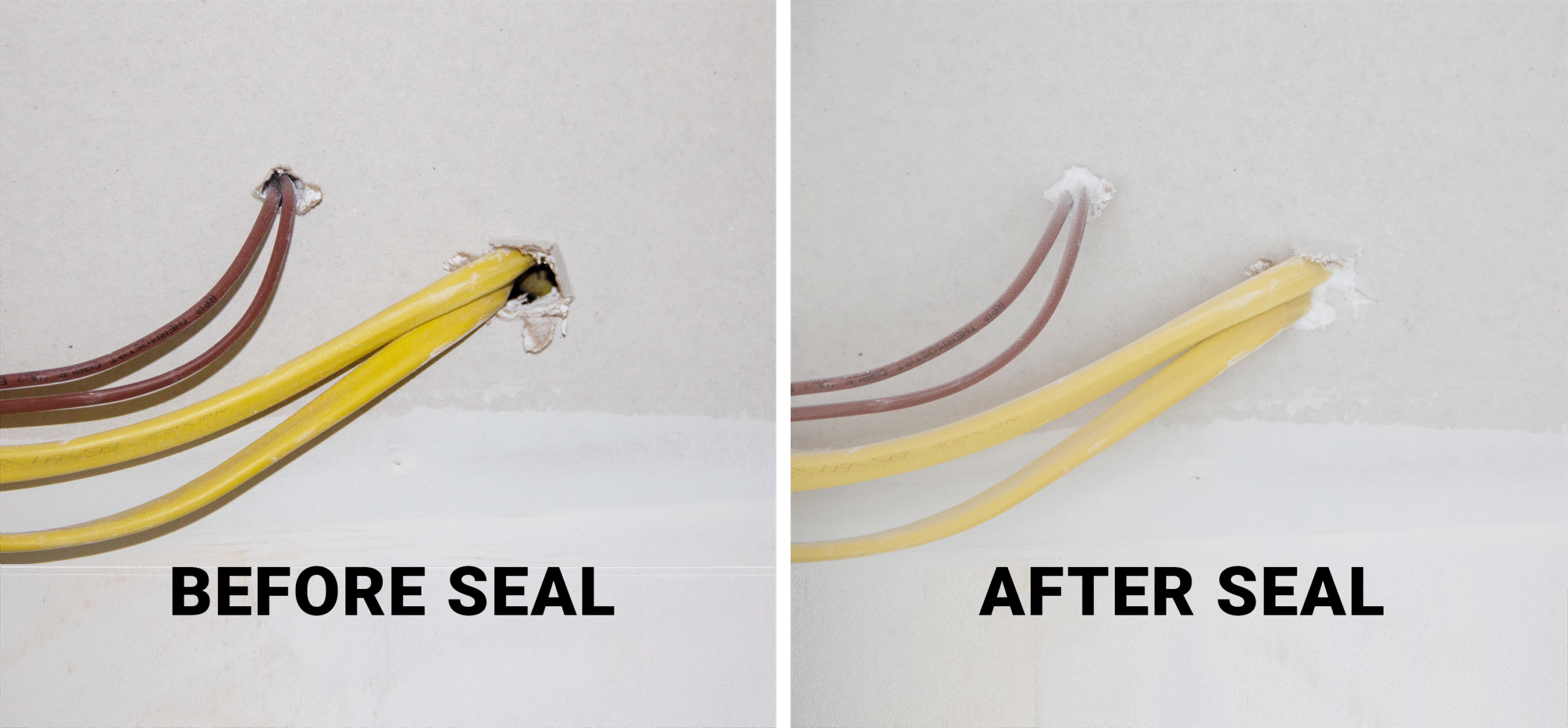

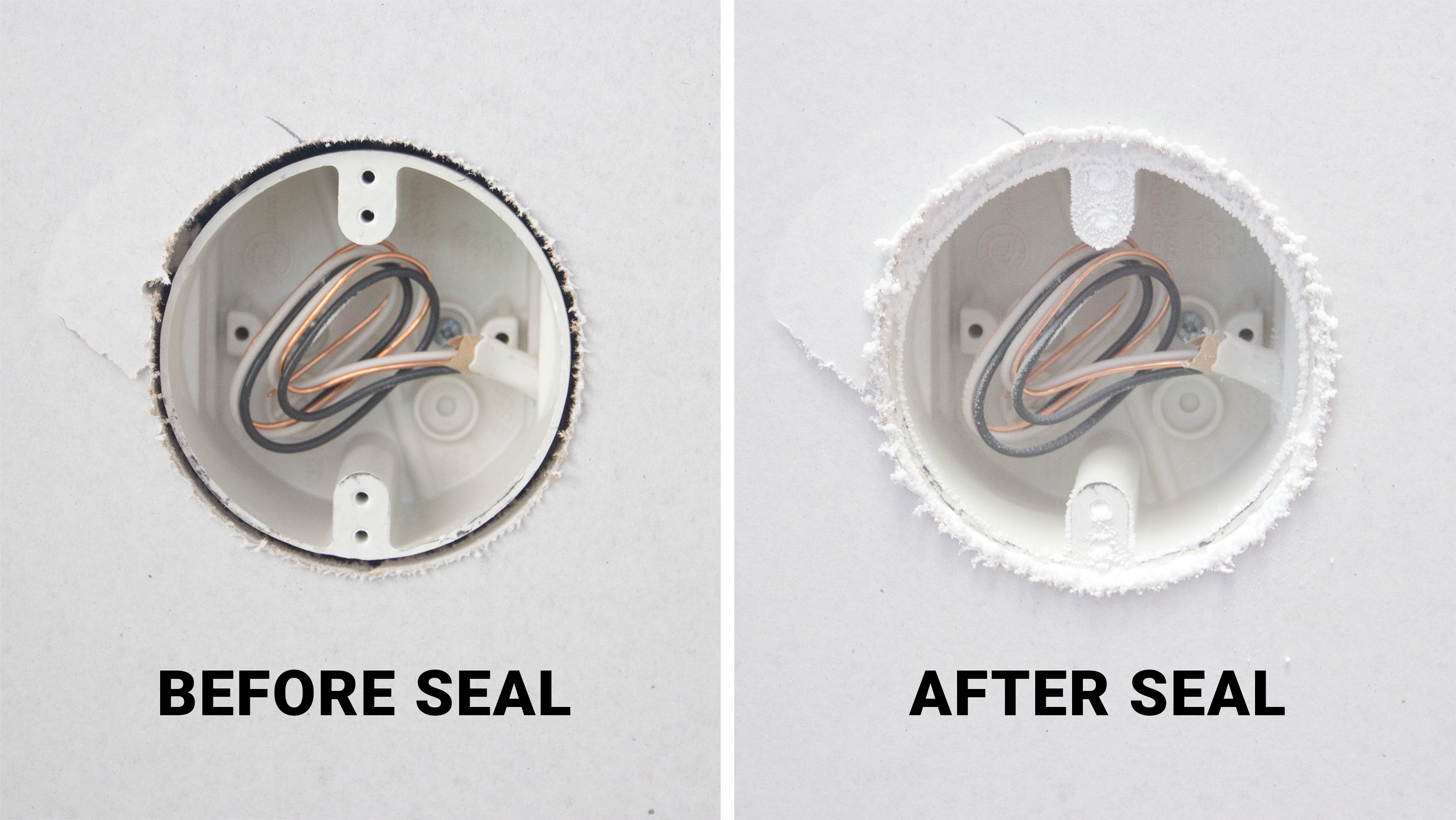

The AeroBarrier system works by creating positive pressure inside the space, forcing air to flow from areas of higher pressure to areas of lower pressure through leaks. This airflow draws the atomized, nontoxic fog of sealant into gaps, where it bonds to seal them. These gaps are typically found in areas such as electrical switches and around windows and doors.

The AeroBarrier process is fully automated and monitored in real time by a continuous blower door test, ensuring complete coverage and optimal performance, sealing down to your desired ACH. AeroBarrier technology is renowned for its ability to detect and seal.

Discover Our Process

1

Preparation and Setup

Protect finished surfaces/openings and set up equipment. The AeroBarrier process begins by preparing the job site. AeroBarrier is ideally performed after drywall is installed, in between first and final mudding. Plastic or tape is used to protect finished surfaces like windowsills and countertops, while openings such as fireplaces and air vents are sealed off to prevent unintentional sealing.

Seal stations are then brought into the house and placed strategically around the interior of the house for an even distribution of sealant.

2

Pressurization

Positive pressure forces sealant into the leaks and gaps. A blower door is installed and is connected to a centrifugal fan via plastic layflat. The AeroBarrier seal stations, fan, and laptop are wirelessly connected to the main control unit (MCU) that controls/monitors the seal in real-time. An initial blower door test is performed to measure pre-seal ACH, the target ACH is inputted into the computer, and the seal begins.

3

Sealing

Inject sealant throughout the home and monitor progress. The AeroBarrier seal stations positioned throughout the home are remotely activated and begin to spray nontoxic, atomized sealant into the space. Positive pressure draws the sealant into leaks, sealing cracks up to ½ inch.

A continuous blower door monitors the ACH50 rating every 10 seconds. Once the target ACH is reached, the seal stations are shut off.

4

Certification & Cleanup

The Seal Certificate is created, and equipment is packed up. After sealing is complete, the AeroBarrier software generates an Envelope Sealing Report to verify the ACH. This report is then archived.

Protective coverings on windowsills and countertops are removed, and work can resume in the house just 30 minutes later.